K24 LSZH Subway Signalling Cables

Applications :

- The cables are designed for remote control and teletransmission in underground railway networks. The cables can be laid in channel, cable tray, or on hook supports, along suburban railway lines electrifi ed at maximum 1500V DC.

Standards :

- AFNOR NF F 55-624

|

|

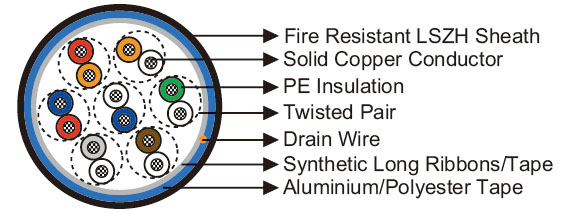

Construction :

- Conductors : Solid copper conductor, 0.5/0.6/0.9 mm nominal diameter.

- Insulation : Polyethylene insulation.

- Cabling Element : Each two conductors are twisted together to form a pair.

- Stranding : For cables less than 15 pairs, pairs are helically stranded in concentric layers to form the cable core.For cables from 21 to 112 pairs, pairs are stranded in concentric layers or bundles to form the cables core.

- Core Wrapping : One or more synthetic long ribbons or tapes are arranged on the cable core.

- Screen : Aluminium/Polyester tape.

- Drain Wire : A tinned copper drain wire, 0.5mm nominal diameter.

- Sheath : Fire retardant LSZH.

Optional :

- Armoured Cables: For armoured cable, one or more tape(s) is (are) helically applied with overlap on the screen to form a bedding, and double steel tapes armour with a halogen-free fi re retardant outer sheath are applied on the bedding.

Electrical Characteristics at 20 °C :

-

Nominal Conductor Diameter mm 0.5 0.6 0.9 Minimum Insulation Resistance MΩ.km 5000 5000 5000 Maximum Operating Voltage V 200 200 400 Maximum Permissible Current A 0.25 0.35 0.80

Mechanical and Thermal Properties :

- Minimum Bending Radius : 7.5×OD (unarmoured); 10×OD (armoured).

- Temperature Range : -40°C to +60°C (during operation); -20°C +50°C (during installation).

Dimensions and Weight :

Unarmoured K24 Cables A-2Y(L)H n×2×0.5/0.6/0.9

| Cable Code | Number of Pairs (n) |

Nominal Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 0.5mm Conductor, 0.9mm Insulated Wire | ||||

| RS/K24-2Y(L)H-2P0.5 | 2 | 1.0 | 6.0 | 55 |

| RS/K24-2Y(L)H-3P0.5 | 3 | 1.0 | 6.5 | 65 |

| RS/K24-2Y(L)H-5P0.5 | 5 | 1.0 | 7.0 | 80 |

| RS/K24-2Y(L)H-7P0.5 | 7 | 1.0 | 8.0 | 95 |

| RS/K24-2Y(L)H-10P0.5 | 10 | 1.0 | 9.0 | 120 |

| RS/K24-2Y(L)H-15P0.5 | 15 | 1.2 | 10.5 | 150 |

| RS/K24-2Y(L)H-21P0.5 | 21 | 1.2 | 12.5 | 185 |

| 0.6mm Conductor, 0.96mm Insulated Wire | ||||

| RS/K24-2Y(L)H-2P0.6 | 2 | 1.0 | 6.5 | 65 |

| RS/K24-2Y(L)H-3P0.6 | 3 | 1.0 | 7.0 | 70 |

| RS/K24-2Y(L)H-5P0.6 | 5 | 1.0 | 8.0 | 90 |

| RS/K24-2Y(L)H-7P0.6 | 7 | 1.0 | 8.5 | 110 |

| RS/K24-2Y(L)H-10P0.6 | 10 | 1.2 | 10.0 | 140 |

| RS/K24-2Y(L)H-15P0.6 | 15 | 1.2 | 11.5 | 175 |

| RS/K24-2Y(L)H-21P0.6 | 21 | 1.2 | 13.5 | 225 |

| 0.9mm Conductor, 1.5mm Insulated Wire | ||||

| RS/K24-2Y(L)H-2P0.9 | 2 | 1.0 | 8.5 | 95 |

| RS/K24-2Y(L)H-3P0.9 | 3 | 1.0 | 9.0 | 110 |

| RS/K24-2Y(L)H-5P0.9 | 5 | 1.0 | 10.5 | 150 |

| RS/K24-2Y(L)H-7P0.9 | 7 | 1.2 | 12.0 | 185 |

| RS/K24-2Y(L)H-10P0.9 | 10 | 1.2 | 13.5 | 245 |

| RS/K24-2Y(L)H-15P0.9 | 15 | 1.4 | 15.0 | 340 |

| RS/K24-2Y(L)H-21P0.9 | 21 | 1.4 | 19.0 | 435 |

Armoured K24 Cables A-2Y(L)HBH n×2×0.5/0.6/0.9

| Cable Code | Number of Pairs (n) |

Nominal Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

|

| Inner | Outer | ||||

| RS/K24-2Y(L)HBH-2P0.5 | 2 | 1.0 | 1.0 | 10.0 | 195 |

| RS/K24-2Y(L)HBH-3P0.5 | 3 | 1.0 | 1.0 | 10.5 | 205 |

| RS/K24-2Y(L)HBH-5P0.5 | 5 | 1.0 | 1.0 | 11.0 | 230 |

| RS/K24-2Y(L)HBH-7P0.5 | 7 | 1.0 | 1.0 | 12.0 | 255 |

| RS/K24-2Y(L)HBH-10P0.5 | 10 | 1.0 | 1.0 | 13.0 | 295 |

| RS/K24-2Y(L)HBH-15P0.5 | 15 | 1.0 | 1.2 | 14.5 | 345 |

| RS/K24-2Y(L)HBH-21P0.5 | 21 | 1.0 | 1.2 | 16.5 | 400 |

| 0.6mm Conductor, 0.96mm Insulated Wire | |||||

| RS/K24-2Y(L)HBH-2P0.6 | 2 | 1.0 | 1.0 | 10.5 | 200 |

| RS/K24-2Y(L)HBH-3P0.6 | 3 | 1.0 | 1.0 | 11.0 | 210 |

| RS/K24-2Y(L)HBH-5P0.6 | 5 | 1.0 | 1.0 | 12.0 | 245 |

| RS/K24-2Y(L)HBH-7P0.6 | 7 | 1.0 | 1.0 | 12.5 | 285 |

| RS/K24-2Y(L)HBH-10P0.6 | 10 | 1.0 | 1.2 | 14.0 | 330 |

| RS/K24-2Y(L)HBH-15P0.6 | 15 | 1.0 | 1.2 | 15.5 | 385 |

| RS/K24-2Y(L)HBH-21P0.6 | 21 | 1.0 | 1.2 | 18.0 | 450 |

| 0.9mm Conductor, 1.5mm Insulated Wire | |||||

| RS/K24-2Y(L)HBH-2P0.9 | 2 | 1.0 | 1.0 | 12.5 | 260 |

| RS/K24-2Y(L)HBH-3P0.9 | 3 | 1.0 | 1.0 | 13.5 | 285 |

| RS/K24-2Y(L)HBH-5P0.9 | 5 | 1.0 | 1.0 | 14.5 | 345 |

| RS/K24-2Y(L)HBH-7P0.9 | 7 | 1.0 | 1.2 | 16.0 | 395 |

| RS/K24-2Y(L)HBH-10P0.9 | 10 | 1.0 | 1.2 | 18.0 | 485 |

| RS/K24-2Y(L)HBH-15P0.9 | 15 | 1.0 | 1.4 | 19.5 | 610 |

| RS/K24-2Y(L)HBH-21P0.9 | 21 | 1.0 | 1.4 | 24.0 | 735 |

|

|

|

|

|

|

Impact Resistant |

Mineral Oil Resistant |

Acid&Alkaline Resistant |

Laid In conduit |

Low Toxicity |

|

|

|

|

|

Flame Retardant NF C32-070-2.1(C2) IEC 60332-1/EN 50265-2-1 |

Fire Retardant NF C32-070-2.2(C1) IEC 60332-3/EN50266 |

Zero Halogen IEC 60754-1/NF C20-454 EN 50267-2-1 |

Low Smoke Emission IEC 61034/NFC20-902 EN 50268/NF C32-073 |

Low Corrosivity EN 50267-2-2/NF C32-074 IEC 60754-2/NF C20-453 |